Polymer Coating Machine

Automatic Polymer Coating Machine

Polymer coating is an emerging surface treatment technique replacing conventional zinc phosphate coating in forging industries. It is an eco-friendly process that promotes lean manufacturing, reduces operating cost and inventory.

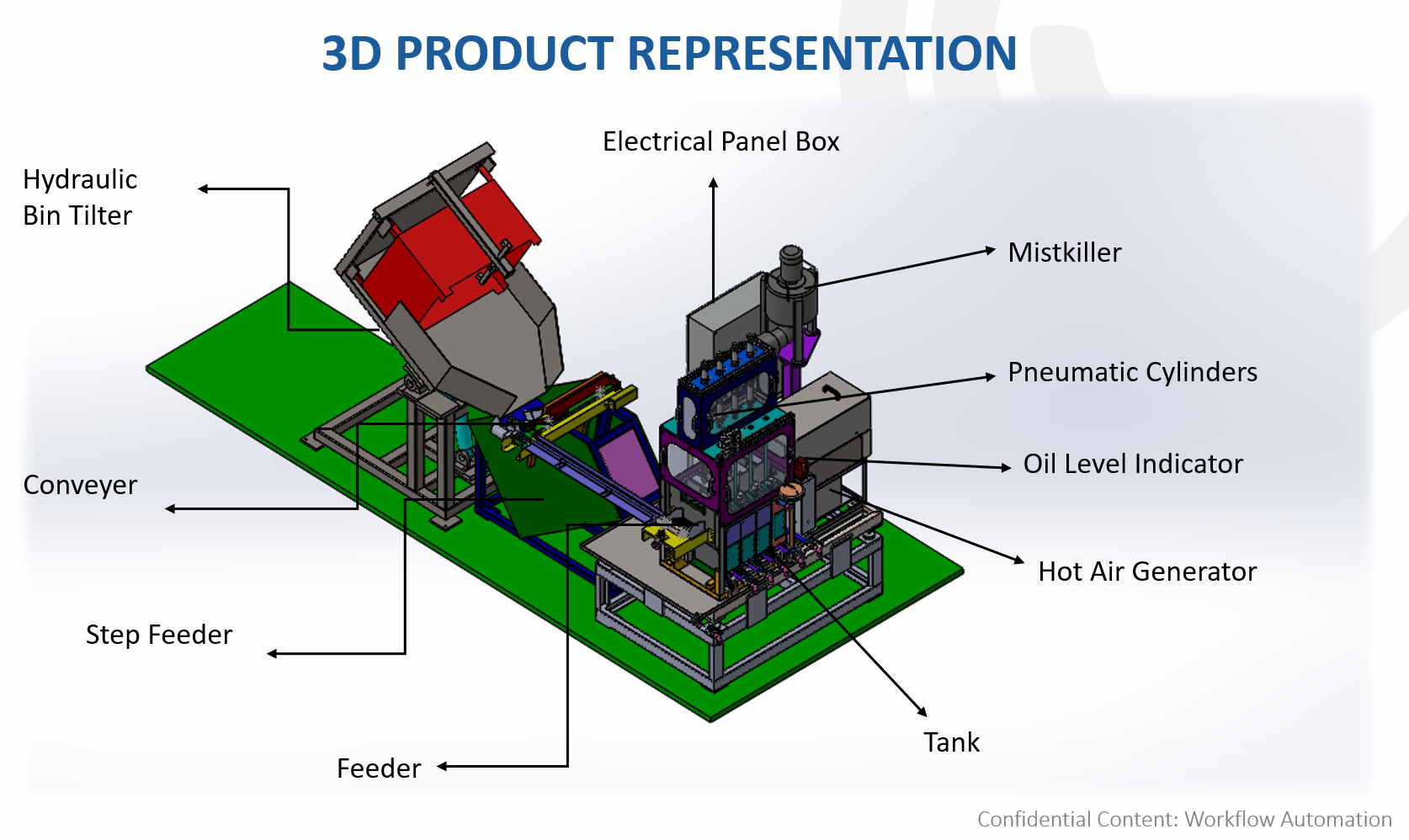

WFA’s Polymer Coating Machine completely automates four step surface treatment process that can be directly incorporated in the forging line.

- Zinc phosphate coating based lubricant systems involves different chemicals that lead to hazardous waste handling and disposal.

- The majority of the baths and used water cannot be recycled and must be treated as hazardous waste.

- The process, pollutes the baths with heavy metals like lead and cadmium.

- In addition, phosphating process consumes large amounts of water, energy and longer treatment time than new tribological systems.

- Conventional coating also produces a lot of dust while turning and machining.

Polymer Coating Machine Process

- Shot blasted metal pieces are loaded into bin tilter.

- The machine is automated to feed the workpieces into coating tank as per required quantities.

- To remove impurities, the workpieces are initially rinsed with warm distilled water inside the coating tank.

- Then the workpieces are immersed in a tank with water, wax, soap and polymer to uniformly coat the job.

- After coating, the workpieces are dried through hot air generator and are ready for forging.